For millennia, humans have been combining elements and materials together to maximize their strengths and minimize their weaknesses. It’s no different in the packaging industry, where hybrid packaging and multi-layered materials are found nearly everywhere.

Homer’s Iliad is the earliest description of the Chimera, a terrifying mythical beast. In the epic poem, it’s described as “a thing of immortal make, not human, lion-fronted and snake behind, a goat in the middle, and snorting out the breath of the terrible flame of bright fire.”

In Greek mythology, there is a famous tale wherein the hero Bellerophon fights this mighty creature. As the story goes, he is exiled from his homeland, and finds himself in the service of a Greek king. While there, he spurns the advances of the queen, who in turn falsely accuses him of attempting to force himself on her.

The King fears the repercussions of killing a guest, and so sends Bellerophon off to his father-in-law’s court, and tasks the older man with performing the execution. Also reluctant to kill Bellerophon, the father-in-law instead tasks Bellerophon with a mission that he feels will surely end in death. The mission is to kill the Chimera. With a huge body, simultaneously lion, goat and snake, it had been wreaking havoc across the countryside. It was a win-win. Either he kills the beast, or, more likely, his agreement to kill Bellerophon is fulfilled.

Bellerophon ends up taming the legendary steed, Pegasus (yet another hybrid), and flies mounted into battle. The Chimera was too powerful to be injured by normal weapons, but Bellerophon ends up using a lead-tipped spear, which melts in the beast’s fiery throat and suffocates it. Victorious, he returns to the King and is sent away on many more quests – but those are tales for another day.

While it might not be quite so overtly awe-inspiring, packaging is a lot like Pegasus and the Chimera. Taking attributes from different sources and combining them — like these fearsome beasts of yore — makes for a stronger and more terrifying whole. If you only knew what went into the packaging of your milk cartons, you too would feel the awe and fear that the peasants felt as the Chimera swooped down from the clouds to lift them away. Luckily, we at FP International can help with that.

When we think about packaging, it’s easy to think of it in a homogenous sense: cardboard boxes, plastic tupperware, metal shipping containers — you get the picture. While these represent huge parts of the packaging spectrum, what you may not realize is that extremely large portions of the packaging you encounter on a daily basis is made up of many different materials that work together to be more protective, sturdier, or more breathable, depending on what’s being contained.

Looking at each component individually, one can see distinct advantages. Plastic, a la tupperware and packaging materials, is extremely versatile (something we hope is made apparent by our extensive selection of packaging products). It’s easy to print on, cheap to make, and it’s extremely lightweight. It’s the go-to for a lot of household containers and tools simply because it can’t be beat in these categories.

Glass is also fairly common. Glass bottles, baking dishes, and more — it’s heat-resistant, which is why thick glass dishes are great for casseroles. It’s also pretty cheap to make, and mostly recyclable. The obvious downside, however, is that it’s pretty fragile. You can drop a plastic bowl and it’ll be fine, but you’d better not drop that glass bowl of Grandma’s beef stroganoff. Losing a meal, and possibly a toe, doesn’t make a fun evening for anyone.

Paper takes up a good portion of the average shelf, too. The ever-present paper bag, cups, and tissue paper are a part of all our lives, mostly because of their unrivaled versatility. It’s the easiest packaging material to print on and has been used for that purpose for hundreds of years. It’s extremely cheap and can take countless forms, whether it’s formed into a carton or shredded and formed as simple packaging filler.

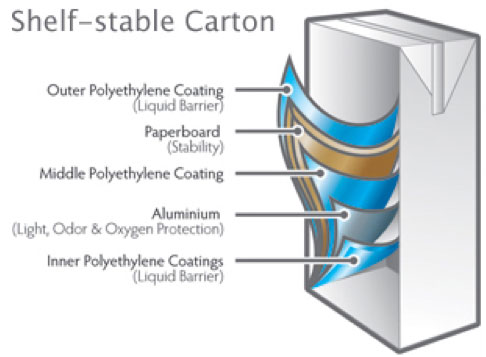

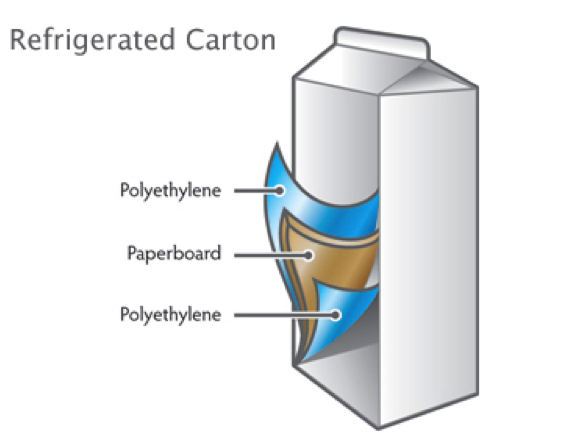

Though all these materials have strengths by themselves, they become even stronger when they are combined. You’re probably familiar with the thick cartons used to contain soup broths, juices, and milk. While to the casual observer it seems that they might just be made of cardboard, they’re actually formed from several layers of different materials. Usually separated between aseptic (shelf-stable) and gable-top (refrigerated), how they’re used defines what they’re made of.

Image source: Carton Council

Image source: Carton Council

An aseptic carton usually carries things like broth and milk alternatives like soy and almond milk. Made from alternating layers of paperboard, aluminum, and polyethylene (plastic) coating, each part serves a useful purpose. The paperboard gives the carton its rigid structure, the aluminum protects the contents from light and oxygen while containing any odors, and the polyethylene acts as a liquid barrier so the paperboard doesn’t become soaked. The gable-top variety is similar, although it skips the aluminum layer because refrigerated goods don’t need the same protections.

Microfibrillated cellulose (MFC) is another interesting marriage of different materials. It’s a fiber extracted from plant waste like wood pulp, used to strengthen paper packaging products (think reinforced butcher paper). The paper/cardboard packaging is coupled with a layer of MFC and benefits from its plastic-like properties. Water and air resistance, plus overall sturdiness could make it a viable alternative to plastic.

Metallized f/ilms are similar to MFC in that they take paper packaging and enhance it, except instead of a layer of cellulose, there’s a layer of metal – usually aluminum. While you may not have noticed, you’re already pretty familiar with metallized films; simply take a look inside your next chip bag. The attractive shininess comes from aluminum.

While that’s mostly used to appeal to the eye, it has real functional benefits, too. It doesn’t crease and puncture like regular aluminum foil would, yet also maintains exceptionally strong barrier properties for both water and air.

Of course, hybridization isn’t just limited to layered packaging and mythical beasts. New technology is emerging that is taking the traditionally inert materials used in packaging and coupling them with sensors that can talk to your phone.

Image source: Packaging Digest

We spoke about smart labels in a previous post, and a relatively new technology called the “connected package” is adding to the ranks of packaging products that send and receive data from a store shelf. Smartphones are able to recognize the subtle patterns in the design of the packaging and display any information the manufacturer wants to relay.

It’s of particular interest in pharmaceuticals, where so much information is conveyed via small text on a little box. Seeing information on your phone, and especially being able to sort through that information to see specific things you need to know, could be extremely useful to anyone that needs medicine. Plus, not only is it easy for consumers to scan, but since you can scan any part of the package, it’s significantly faster for retailers to scan at checkout, saving them time. If more products adapt this design, that could mean noticeably faster checkout times across the board.

Bruce Miller, Vice President of Product Development for Matthews Intl. Corp, discussed the functions of the labels his company produces in an interview with Packaging Digest. When asked about the future of this technology, he stated that “standard packaging that doesn’t connect to the Internet will soon be anachronistic.”

It’s further evidence that the Internet of Things is becoming less a future concept and more just a part of our average, everyday lives. The line between us, our technology, and our goods is becoming increasingly blurred. In a way, I suppose, we’re becoming hybrids ourselves.

While the similarities are clear, there’s one key difference between the hybrid goods I’ve detailed here, and the Chimera and terrifying beasts like it. While these mythological monsters lived only to devour animals and tear men limb from limb, hybrid packaging works for us, making us more efficient and more able to do battle with the dark forces of disorganization and inefficiency.

With the mighty spear of enhanced barrier properties, and the shield of technologically augmented packages, we will forge ahead into a future fraught with danger. If you’re in the packaging business — take heed and arm thyself.

The European Parliament voted for a complete ban on a range of single-use plastic waste across the union in a bid to stop pollution of the oceans. The proposal also called for a reduction in single-use plastic waste for food and drink containers, including plastic cups.

China has long been treated as our planet’s repository for plastic waste. The nation has accepted 45% of the world's total plastic recycling since reporting to the United Nations Comtrade Database began in 1992.

Even before plastic straw bans grew trendy, California was at the forefront of using less plastic and promoting more sustainable living. California pioneered a statewide ban on plastics beginning in 2016, when the state became the first in the U.S. to ban most stores from providing customers with single-use plastic bags, following a successful referendum. [...]