Most of us do not realize the staggering amount of food we throw away in today’s society — and much of it, it turns out, doesn’t need to be disposed of at all. From production, to packaging, to store shelves, to the consumer, there are countless ways for us to fortify our food system and get it to those that need it, rather than to the landfill. Here’s a list of five.

In the United States, 31 percent of our 430 billion pound food supply (at retail and customer levels) went without being eaten in 2010, according to the USDA. That amounts to a frightening 133 billion pounds of perfectly edible food wasted or $161.6 billion if you prefer a fiscal measurement. This cost is felt all the way from the farms that create the food to the people that consume it — not to mention the energy waste of the land, water, and labor that went to produce something that just ended up in a landfill.

It’s a little shocking to think that we waste almost a third of our entire food supply. How can we lose track of so much? There’s no single, clear answer to that question, and solving the problem will require a concerted effort at every level. Whether you’re managing a large factory farm or eyeing up that questionable tray of chicken in the refrigerator, it’s important to make an effort to avoid immediately resorting to sending extra food to the garbage.

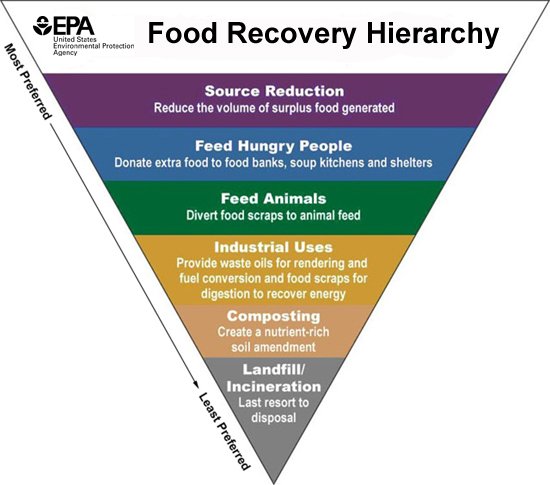

To cut down on this waste, the EPA has created a Food Recovery Hierarchy that lays out the order in which anyone involved in food handling should approach the food waste they produce.

Image source: EPA

Following the hierarchy, the first step should always be source reduction. In your kitchen at home, evaluate how you shop: do you need bulk amounts of perishable food or do you often find yourself with too much? For large businesses, efficiency in the production process is paramount — and we waste a lot of food on farms and in factories due to unreasonably high aesthetic standards.

If that’s not an option, the next step is to donate. Giving extra food that you won’t be able to eat (or as a business, can’t sell), but is still edible, to a local food pantry or charity is a fantastic way to help your community no matter who you are.

If not people, the next step suggest feeding animals. Contacting your local solid waste, county agricultural extension office, or public health agency is a fantastic way to find out how to send your excess vittles to the belly of a hungry creature. If you can’t make that happen, you can always compost. It’s effortless to throw your organic waste into a bin and let nature do the rest, and there are fantastic how-to articles all over the Internet on how to do it properly.

As we at FP International care about packaging innovation and sustainability issues, we have a vested interest in helping mitigate waste in all areas of life. In the food industry, packaging is present every step of the way. Moving and storing goods will always require containment of some kind, and creating more efficient, innovative packaging for food especially can help reduce waste.

The companies that make cartons, containers, and bottles can increase food’s longevity, helping to ensure products get safely from point A to B, and better inform consumers about the freshness of their food. Here are some of the top food companies and innovators that are getting meals into mouths instead of the trash.

In 2014, British multinational supermarket chain Tesco took the unprecedented step to reveal all its food waste data for the previous two years. The 28,500 tons of unused food was exposed for all the world to see. While on the surface, this seems like a self-damning move for a large grocery company, it’s worked well in their favor due to continued, public efforts to decrease those waste numbers. “We do not just want to reduce food waste in our own operations,” the report stated. “We have a shared responsibility to reduce food waste across the value chain wherever it occurs in fields, farms, distribution networks and in our homes.” It was a refreshing splash of honesty — the kind that rarely goes unnoticed by consumers.

Since then, they’ve embarked on a highly publicized campaign to reduce food waste, called “Community Food Connection.” The campaign highlights food donations and other techniques Tesco is using to make sure their food isn’t ending up in landfills. But their efforts don’t end with donating excess product. Their products’ very design facilitates longevity. Take a look at their container for raw chicken breasts:

Image source: Tesco

Anyone that’s ever bought a package of chicken knows that once you break through that plastic wrap, the clock is ticking. Another day or two and you’ll smell that familiar odor of ammonia, and open the door to any number of gray, unappealing lumps of what used to be poultry. While dividing it up and placing it into a new, sealed container right away can help, the meat still turns fairly quickly.

Tesco is combating this issue by producing food in pre-portioned packaging so consumers can “eat one, keep one.” Instead of one large space for contents, having several, smaller portions that separate from one another can ensure that only the needed amount is opened. The rest remains factory-sealed until you need another piece. Tesco has even stated that they aren’t raising prices to match the extra packaging cost, absorbing it in its efforts to incentivize customers to fight waste.

By introducing pre-portioned packaging like this, businesses can make it easy for consumers to make their food last an extra few days. While the additional packaging to preserve food might be of concern, it’s deemed a worthy alternative to both wasted packaging material and food. As Tesco CEO Dave Lewis puts it, “There is no time to waste on food waste.”

We recently wrote about a new beverage carton design that decreases in volume as you use up its contents. This carton has pre-folded creases that bend as the container is squeezed, collapsing flat as it empties.

Not only that, but it bears a valve that is 100 percent airtight, so as the contents are used it doesn’t pull in the air that acts as a major catalyst for spoilage. The valve also prevents spills when it’s dropped, so if you happen to be all thumbs, it might be wise to keep an eye out for this. From an industrial standpoint, this new valve’s production cost is on par with conventional beverage carton valves — meaning you can save more product with better technology at the same cost.

Image source: K-Bis Studio (via Packaging Digest)

This carton, like Tesco’s pre-portioned chicken, tackles the issue of household food waste. So much of that waste can be prevented by using packaging that facilitates freshness and longevity, rather than relying on the consumer to go the extra mile to achieve it themselves. Nobody throws out or neglects good food out of spite — it’s only lack of awareness or options. By designing a product that provides a cost-effective way for businesses to give consumers those options, K-Bis Studios is proving that reducing food waste doesn’t have to be at the cost of time of economic efficiency.

The Timestrip food label is one of the latest advances in smart label technology that gives us active, real-time information on food products. When it comes to the quality of produce, knowledge is power, and this little sticker goes a long way to keep us informed. Before use, the label is completely inert and white and can be exposed to normal temperatures without any effect. After application to the product’s packaging, one only has to push the big, obvious power button to activate it. Timestrip then monitors temperatures for days, weeks, or even months.

How this particular label differs from other, similar technologies that change colors in the event of a temperature breach, is that it provides information as to the duration and severity of the breach. As explained on their website:

“A Timestrip® Food indicator was chosen to monitor a shipment which would take 24 hours to arrive. When the shipment arrived, the indicator showed 4 hours of 5°C breach. This breach could have happened in one long event or from a series of shorter breach events across the 24 hours. The Timestrip® Food indicator could have indicated up to 4 hours of temperature breaches during that 24 hours.”

Image source: Timestrip

The main allure of this type of label is to those in the business of packaging and shipping food. If you receive large shipments of food, it can be beneficial to instantly have access to information about any safety hazards associated with each delivery, and if the incident was severe enough to warrant a denial. Especially for restaurants and distributor, this is preferable than opening packages of perishables later, only to find that the quality has been compromised somewhere in the transportation process.

Timestrip isn’t the only revolutionary smart label technology that’s hitting the market. More advanced products are in development, with the ability to even detect spoilage within packages. This technology has the potential to vastly reduce our food waste because it could render the ineffective and confusing sell-by dates we currently use obsolete. Many people throw out quality food only because it’s passed that poorly-defined cutoff period; it’s apparent that we need something more accurate. By replacing an almost arbitrary number with something that provides actual, real-time data on whether your food is edible or genuinely spoiled is a clear solution to a massive part of the household food waste issue.

Modified Atmosphere Packaging (MAP) is a technique that is fairly widely utilized in today’s food industry. Essentially, it’s a blanket term that refers to a process that replaces the natural air inside a package with a specially formulated combination of gases that keeps the contents fresher longer, chiefly oxygen, carbon dioxide, and nitrogen.

It’s a delicate process, as too much of any one gas can cause unwanted flavors or altered appearances in product, and each company has different formulations that they prefer based on the product they’re packaging. This makes the selection of barrier packaging a sensitive issue, especially for vegetables. The packaging needs to let just enough oxygen enter from the outside as is consumed by the contents. In most cases, specialized plastic wrap is used, but there are new, experimental materials being tested like microfibrillated cellulose, a plant-based fiber material.

Image source: Pack World

MAP is almost always applied to fruits, vegetables, meat, and seafood because it’s excellent at preserving color. Many businesses prefer their meat to have a distinct, bright red color and want their vegetables to be equally eye-catching. By regulating gases within containers, they can retain this fresh appearance until the container is opened. This is one of the reasons ground beef looks so delicious in the store, but a day or two after it’s opened it quickly browns.

Other techniques achieve a similar effect, like vacuum-sealing, which eliminates gas from a container completely. While this can be easier, it makes products take on a darker color, especially meat. It can also make soft products look a bit squished. Some businesses have adopted this appearance as a signature look, like PRE Brands, a Chicago-based beef company.

In most cases, for a balance of shelf-life and appearance, MAP is the best technique on the market unless you’re packaging something like cheese, where the color isn’t affected by the surrounding environment. In that case, vacuum-seal away!

Technology like oxygen scavengers is also being used to control the air around your food. These little packets operate much like the silica packets you see in shoeboxes, but instead of absorbing moisture, they absorb oxygen. By using these, food companies can create a sort of middle ground between MAP and vacuum sealing.Whichever method is used, it’s a fact that controlling the air that contacts food product is a tried-and-true method of making sure product

Whichever method is used, it’s a fact that controlling the air surrounding food is a tried-and-true method of making sure it stays fresh all the way from the farm or factory to the hands of the consumer.

British food manufacturer Northern Foods recently revamped their Goodfella’s pizza box to a lighter, thinner version. It’s a simple change, but it’s worked wonders for the company. First, according to a survey by wrap.org, it decreased the number of damaged pizzas reaching consumers by 75 percent due to less wiggle room within the box. It also reduced the total amount of material used to make the boxes by 4,000 tons in a year.

Image source: Goodfella’s

Reducing package size and weight where possible is a tremendous way packaging businesses can reduce both environmental and shipping costs. Less material being put into packaging means less money spent on that material. In the case of the pizza boxes mentioned above, they allow more products to be stacked on a pallet or put into a truck, which means more efficient shipping. The business needs fewer vehicles on the road, leading to fewer emissions, vehicle purchases or rentals, and wages paid to drivers.

It’s another solution that reduces food waste before the product is even in the hands of a consumer. The more we can do to fix this problem from the top of the Food Recovery Hierarchy — reduction at the food source — the easier it will be to work on the issue on lower levels.

In the end, what’s going to go furthest to help us cut down our food waste isn’t just a lighter box or packaging technique — it’s education. It’s important that more people realize that we’re getting rid of staggering amounts of a valuable resource that could go to people that need it, or at least be used in a way that’s productive rather than just wasting away. If business owners make an effort to reduce waste within their companies, and consumers try to better understand how to extend the longevity of the food they buy, we could easily waste less than a third of the entire supply.

The more information we put on packages, in our mission statements, and on our websites, the more people will be made aware that this is a genuine problem that every one of us can help stop easily. By incorporating efficiency into both our personal and business philosophies, together we can ensure a future where goes where it needs to.

The European Parliament voted for a complete ban on a range of single-use plastic waste across the union in a bid to stop pollution of the oceans. The proposal also called for a reduction in single-use plastic waste for food and drink containers, including plastic cups.

China has long been treated as our planet’s repository for plastic waste. The nation has accepted 45% of the world's total plastic recycling since reporting to the United Nations Comtrade Database began in 1992.

Even before plastic straw bans grew trendy, California was at the forefront of using less plastic and promoting more sustainable living. California pioneered a statewide ban on plastics beginning in 2016, when the state became the first in the U.S. to ban most stores from providing customers with single-use plastic bags, following a successful referendum. [...]